LIU Weicheng, a postgraduate student of CALM (first author), Dr. WANG Zhiwen and Professor ZHENG Hongyu (corresponding authors), published a paper entitled “Simultaneous laser in-situ generation of graphene and micro-textures on ductile iron and their effectson tribological properties” in Journal of Materials Research and Technology.

This paper presents a method for efficient preparation of microtexture arrays on ductile iron materials while inducing graphene production. In this paper, the surface of ductile iron can be prepared with controllable size and density of microtexture arrays by simple laser scanning for the characteristics of ductile iron itself.

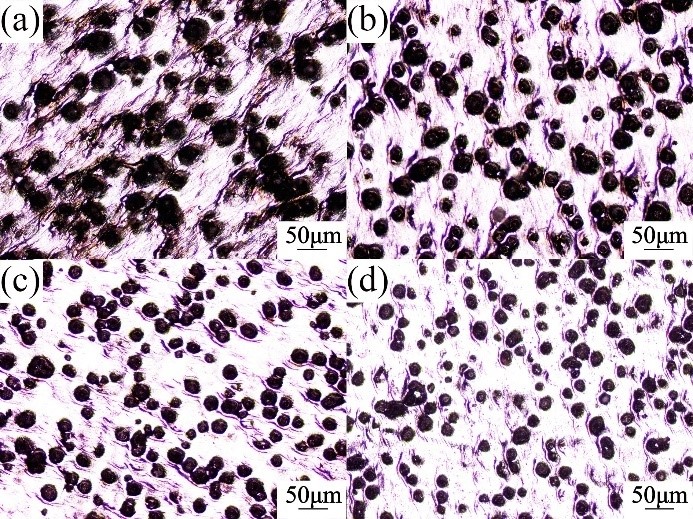

In this paper, by changing and adjusting the laser power density and scanning speed, different densities of microtexture structures were prepared on the samplesurface. Their effects on the tribological properties were investigated and find the optimal density of microtexture array.

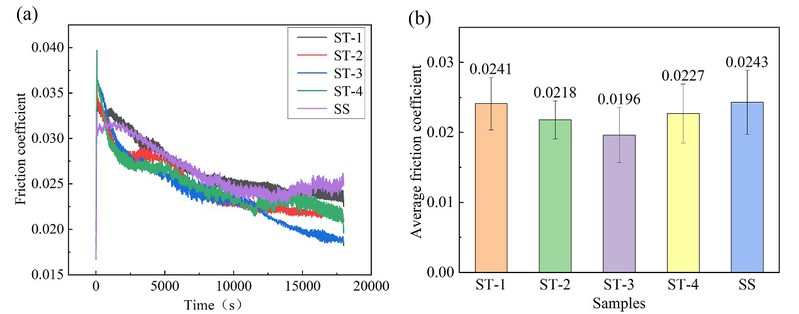

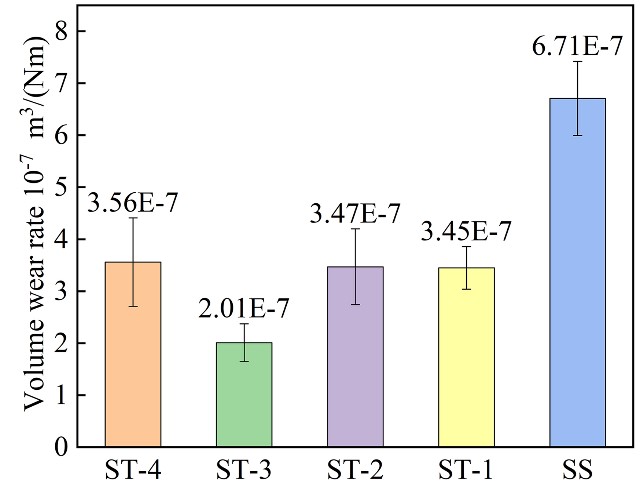

The Research found that microtexture arrays can effectively increase the surface hardness of workpieces and improve the surface tribological properties. Among them, the dimples with area density of 20% and average diameter of 36 μm (ST-3) can reduce the volume wear rate to 70%.

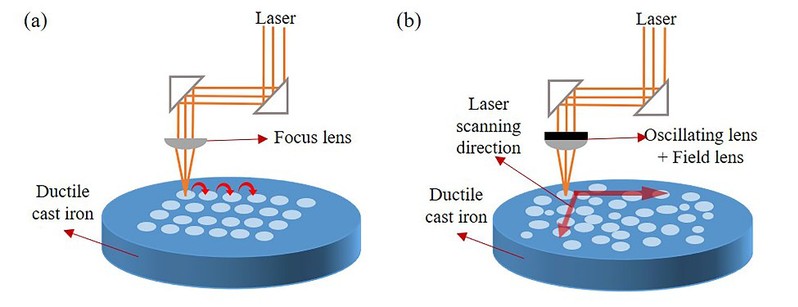

Fig. 1 Laser scanning mode (a) spot-by-spot ablation; (b) parallel scanning.

Fig.2 Optical images of laser surface textured samples with different scanning speeds (a)1m/s (ST-1) (b) 1.5m/s (ST-2) (c) 2m/s (ST-3) (d) 2.5m/s (ST-4).

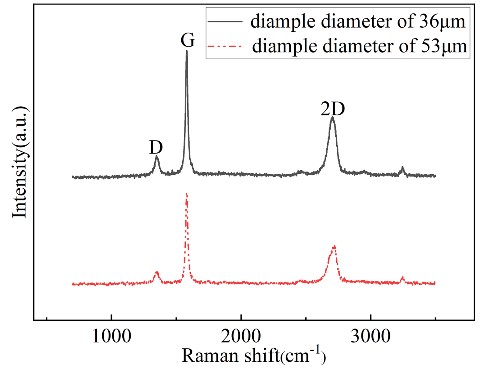

Fig. 3 Representative Raman spectrum of laser-induced dimple.

Fig. 4 Comparison of friction coefficient and average friction coefficient with different area density of textures: (a) friction coefficient curve; (b) average friction coefficient in stable curve stage.

Fig. 5 Comparison of Volume wear rate of different samples.